As automobiles become increasingly intelligent, drivers expect more than just basic driving functions; they desire a more humanized and convenient driving experience, such as automated parking assistance and keyless entry. In recent years, with the expansion of the electric vehicle market, the automotive industry has become highly reliant on semiconductors for its power systems. The Body Control Module (BCM) is a crucial component in automotive engineering, serving as a central hub that integrates various functions and facilitates data exchange between different electronic devices, ensuring driving safety and comfort.

The BCM, also known as the Body Computer, is the management center and information hub of a vehicle, comparable to the human brain or the CPU in a computer. It receives external signals and controls the body systems, responding with appropriate functions. The scope of its control has expanded significantly over the years, encompassing body devices (windows, wipers, mirrors), safety devices (anti-theft systems, remote start), lighting systems (LED headlights, fog lights, indicators), fuel pumps, and heating and air conditioning systems.

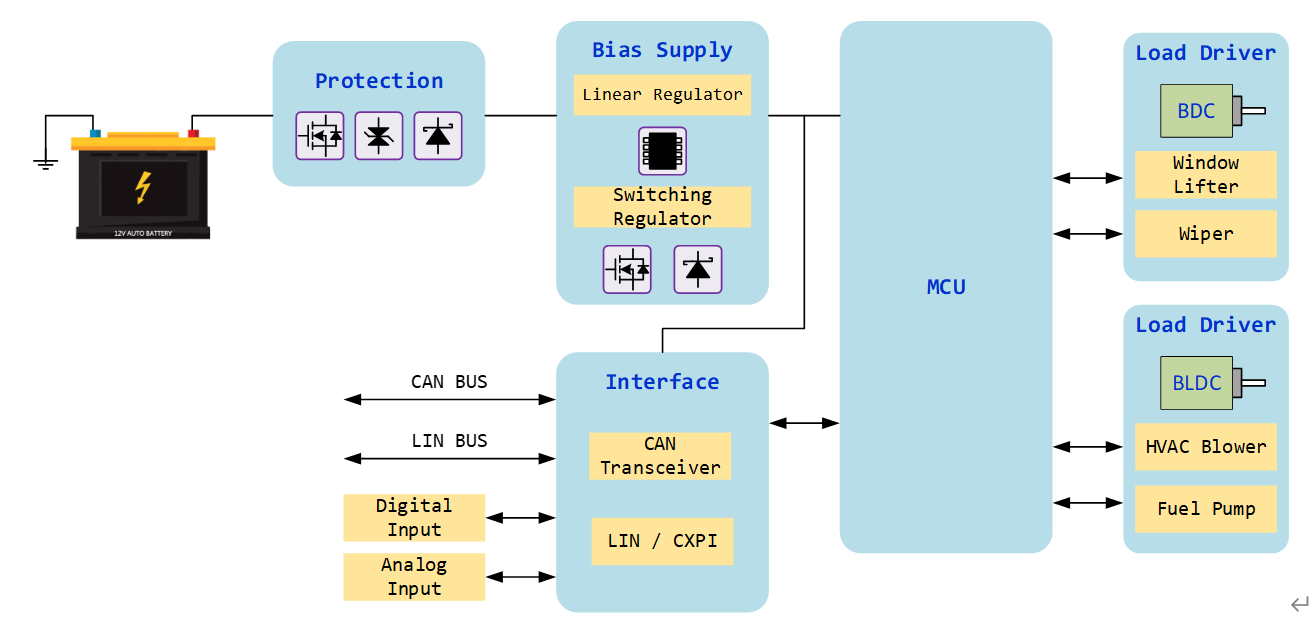

The diagram below illustrates the solutions provided by Taiwan Semiconductor at different stages of the BCM.

Protection

During automotive repair or assembly, reverse connection of the vehicle’s power supply can expose the vehicle controller to damage from reverse voltage. Automotive regulations and OEMs have established requirements for reverse polarity protection in vehicle controllers to mitigate this risk. As a result, reverse polarity protection circuits have become commonplace. These circuits primarily consist of diodes, TVS diodes, or MOSFETs.

TVS

As a vehicle is in motion, components interact with each other, creating potential interference. A TVS diode in this context can be likened to a door damper. Imagine two cabinets: one with a door damper and the other without. If both doors are closed with the same force, the door without the damper will slam shut quickly and loudly, potentially damaging the cabinet over time. However, the door with the damper will close more gently, protecting the cabinet.

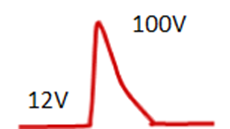

Load Dump TVS

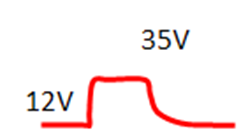

Beyond component-to-component interference, the alternator charging the lead-acid battery can generate transient voltage spikes, especially when driving over rough roads that cause the battery connections to loosen. These high-voltage spikes can last for a relatively long duration and can damage electronic components.

Taiwan Semiconductor’s Load Dump TVS is designed to protect electronic circuits from these transient voltage spikes caused by loose lead-acid battery connections. This component can withstand the transient voltage spikes generated by the alternator and protects automotive electronics, meeting the ISO 7637-2 and ISO 16750-2 test standards. Additionally, it can also meet the IEC 61000-4-2 (Level 4) and ISO 10605 (Level L4) test specifications.

Bias Supply

A 12V lead-acid automotive battery is typically converted to 3.3V, 5V, or other voltage levels using a voltage regulator (linear or switching) to power CAN bus/LIN bus transceivers and MCUs.

There are two primary types of voltage regulators:

- Linear Regulator (LDO) Linear regulators, often referred to as LDOs, are suitable for converting higher input voltages to lower output voltages. LDOs typically consume relatively low power and are well-suited for applications requiring low noise, low current, and a small input-output voltage differential, providing a stable output voltage.

- Switching Regulator Switching regulators primarily consist of MOSFETs and diodes. By periodically switching the circuit on and off based on a duty cycle (the percentage of time the circuit is on), they generate a stable output voltage. Switching regulators offer a wide range of applications, high efficiency, and ease of use.

Interface

CAN bus/LIN bus transceivers primarily serve as communication channels. Think of them as nerves in the human body. When the body receives a stimulus, nerves transmit the signal to the brain. Similarly, when a vehicle receives an external signal (digital input/analog input), it is transmitted to the MCU via the CAN bus or LIN bus. The CAN bus is the primary network, while the LIN bus is a secondary or sub-network.

Load Driver

Once the BCM receives external signals and processes them through the microcontroller unit (MCU), the MCU sends these signals to the corresponding loads, such as body devices (windows, wipers, mirrors).

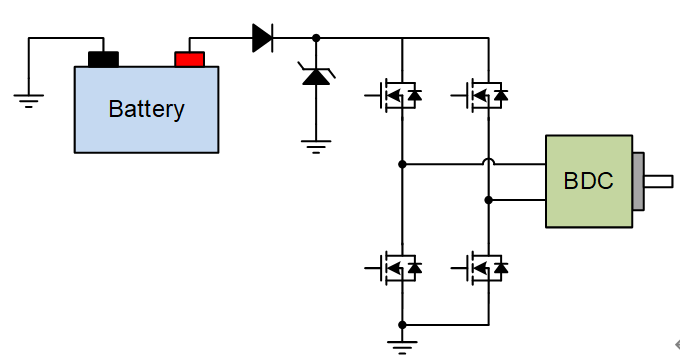

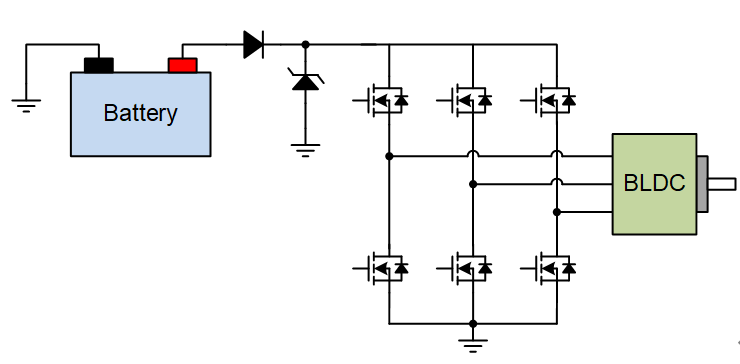

Many of these devices contain motor-driven loads. Motors are primarily classified into brushed DC (BDC) motors and brushless DC (BLDC) motors. MOSFETs are used to control the direction and speed of these motors.

- Brushed DC (BDC) Motor BDC motors are a low-cost solution and are commonly used for small load control in automobiles, such as seat adjustment, window switches, and wipers. BDC motors typically use four MOSFETs and a commutator for commutation, making them easy to operate and cost-effective.

- 3-phase brushless DC (BLDC) Motor BLDC motors employ six MOSFETs and offer low power loss, high reliability, and low noise, making them the preferred choice for high-power applications. With the increasing adoption of electric motors in automobiles, costs are decreasing, making brushless motors increasingly popular in the market.

Additionally, BDC motors have a commutator structure compared to BLDC motors, resulting in more audible noise during operation. To illustrate this, BDC motors can be likened to old ceiling fans that produce a humming sound, while BLDC motors are akin to newer standing fans that operate more quietly.

Feature | Brushed DC (BDC) Motor | Brushless DC (BLDC) Motor |

|---|---|---|

Operation | Easy | High controllability |

Cost | Low | Low loss |

Service life | Short (brushes wear easily) | Long |

Noise | Noisy (due to brushes) | Low noise |

Cooling | Easy to cool | |

Applications | 1. Window/sunroof control | 1. EPS (Electric Power Steering) |

Products

Read more articles

- The Role of MOSFETs in Anti-lock Braking Systems (ABS)

- Beyond Braking: Advanced Driver Assistance Systems (ADAS) for a Safer Driving Experience

- Battery management system (BMS): Protecting and Managing Your Electric Vehicle

- Advanced LED Solutions for Enhanced Vehicle Visibility

- Power Components for On-Board Chargers (OBC): A Comprehensive Overview

- MOSFETs and Diodes: Key Components in Reverse Polarity Protection

- Sensor Fusion for Supplementary Restraint Systems (SRS)