Sustainability

Sustainability

Air Pollution Management

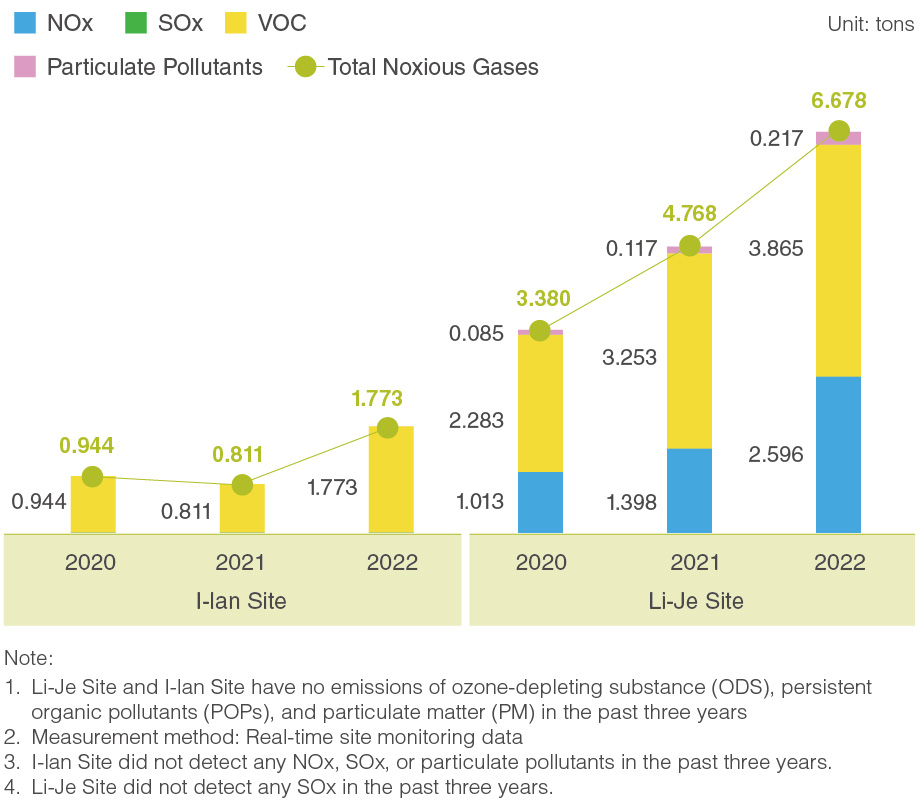

TSC is dedicated to preventing air pollution and implementing environmental protection measures. The company’s air pollutant emissions, which include acid and alkaline waste gas, as well as volatile organic waste gas (VOCs), are effectively managed through various control equipment. These include acid and alkaline scrubbing towers and zeolite rotor incineration systems. Continuous monitoring is conducted using flame ionization detector (GC-FID systems) to ensure that the control equipment operates efficiently and meets regulatory standards. In 2022, due to the expansion of production capacity, there was a slight increase in actual VOC emissions compared to 2021.

Air Pollution Control Monitoring

TSC complies with the “Air Pollution Control and Emissions Standards for the Semiconductor Industry” to manage emissions and conducts regular audits, both internally and externally, to monitor air pollution prevention equipment. In 2022, TSC’s I-lan and Li-Je sites had average VOC emissions of 0.202kg/hr and 0.33kg/hr, respectively, surpassing the emission standards set by the Ministry of Environment.

Waste Gas Treatment

TSC emits primary air pollutants that can be classified as acid and alkali waste gas, as well as volatile organic waste gas. TSC utilizes specialized treatment equipment and processes that are tailored to the characteristics of each type of waste gas.

| Air Pollutant Type | Treatment Method |

| Acid/alkaline Exhaust Gas | Acid and alkali wastes are collected in an acid/waste scrubbing tower for appropriate treatment, ensuring that the resulting wastes comply with emission standards. |

| Volatile Organic Waste Gas | Li-Je Site: Volatile organic compounds (VOCs) are adsorbed and concentrated using a zeolite rotor. This is followed by a continuous high-temperature desorption process and catalytic incineration. As a result, the treated waste gas meets emission standards, achieving a reduction rate of over 90% for volatile organic waste gas. I-lan Site: VOCs are treated using scrubbing towers to remove VOCs from the waste gas. The resulting waste liquid is then discharged into the wastewater system. Since the concentration of VOCs is lower at the I-lan Site compared to the Li-Je Site, scrubbing is the preferred treatment method. This eliminates the need for concentrated purification using zeolite rotor adsorption. |

The scrubber tower at TSC’s Li-Je Site utilizes a parallel method to process both acidic and alkaline waste gases. In the event of an emergency, the remaining equipment can be adjusted to handle the target exhaust treatment, while also coordinating with the production line to prevent air pollution. Furthermore, the zeolite rotor continuous incineration (RCO) system, which is employed to treat volatile organic exhaust gases, can be switched to the activated carbon tower in parallel during emergencies. This allows for simultaneous coordination with the production line to minimize environmental impact.